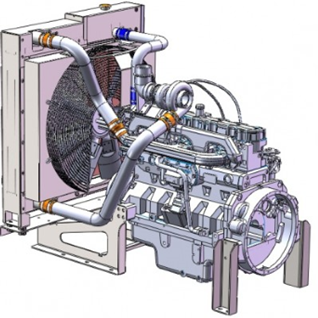

Diesel Radiator Company has cooling packages designed and ready for production, for a wide range of engine brands.

Corrosive Environment? Off Shore? Most common coatings are galvanizing the steel or using stainless steel and epoxy coating the core. Solder coated fins and Heresite coated cores also available.

On Highway and transit bus applications Diesel Radiator Company makes radiators for truck and bus applications. Diesel Radiator supplies radiators to many transit authorities across the country and can also retrofit or reverse engineer cooling packages for drop-in replacement.

Tube OD | CLBR | Min Straight Length between bends | Min Straight Length for Bead | Max Angle |

1.75 | 1.8 | 4.5 | 1.1 | 110 |

2.0 | 2.0 | 4.1 | 1.0 | 110 |

2.0 | 3.0 | 3.1 | 1.0 | 120 |

2.25 | 3.4 | 3.4 | 2.0 | 120 |

2.5 | 2.5 | 5.1 | 2.0 | 95 |

2.5 | 3.8 | 3.9 | 2.0 | 110 |

3.0 | 3.0 | 6.1 | 1.1 | 90 |

3.0 | 4.5 | 4.6 | 1.1 | 110 |

4.0 | 4.5 | 10.5 | 2.13 | 90 |

5.0 | 5.0 | 13.0 | 2.06 | 90 |

Viking Power Products

Lewisville, PA 19351, United States

PO Box 127

Order Now At: (877) 255-8860

Copyright © 2019 Viking Power Products Co.

All rights reserved.